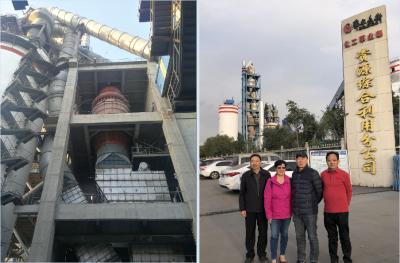

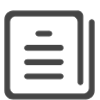

01.Built-in direct combustion hot blast furnace

Using the built-in burner to directly heat the gas in the flue, the high temperature flue gas generated by combustion and flue gas heating needed directly mixed and exchanged, no related heat loss, high thermal efficiency, small energy consumption, less land area, less overall investment, and low operation cost.

More Product Series from Tianlong

Product Series from Tianlong